MIAMI (BRAIN) — J&B Importers has built wheels by hand since the Miami-based distributor was founded in 1971. In the early days, current vice president Ben Joannou Jr. and a friend would spend Saturdays building up wheels.

At an event at the company’s headquarters during BRAIN's Miami Dealer Tour Wednesday, Joannou recalled those days.

“We could build about a hundred wheels a day, but that wasn’t nearly enough to supply the whole country with wheels,” he said.

In more recent years, J&B relied on a group of independent contractors, some of whom built wheels in their homes.

“We were one of the last holdouts for handbuilt wheels. ... The main concern was quality,” he said. “We had about a 1 percent defect rate."

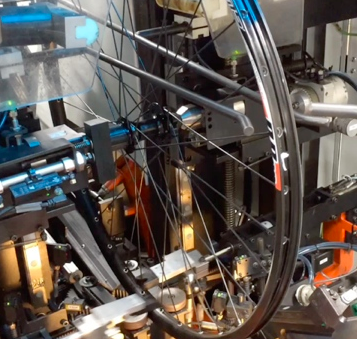

So about four years ago, the distributor, which has 11 warehouses in the U.S., invested heavily in a new automated wheel-making facility in Miami. The wheel room is in a separate, well-lit and air-conditioned room off the main warehouse floor, and it includes a full array of automated Holland wheel-building machines. Joannou declined to say how much J&B invested in the project, but Holland machines cost well into six figures, and the facility has seven production lines, including two Holland hub-loading machines. The factory now typically produces between 1,200 and 1,600 wheels per day.

Besides the automated machines, J&B still has four stations for handbuilding wheels, usually for custom orders.

Joannou said the automation has reduced the wheel defect rate to virtually zero. The machines test the wheels’ trueness and tension, and then a worker inspects each wheel and puts his or her name on a sticker on each rim.

“Occasionally, there is shipping damage or we see failure of a component like a hub, but there are really no wheelbuilding defects.”

Since investing in the automation, J&B’s reputation for quality wheels has improved. So have sales. Joannou said that figuring in the depreciation of the equipment, the cost of producing wheels with the machines is a hair higher than handbuilding, but J&B has not increased its prices.

While hubs, rims and spokes are generally imported, J&B is adding value in the U.S., and is more than able to compete with Asian-made wheels, which are built with the same components (and generally the same Holland machines) but have to be shipped.

Nowadays instead of fewer than a dozen independent wheelbuilders, J&B has about 10 employees working in the wheel facility.

“We have about the same number of people devoted to wheels, but the difference is they are now employees and not subcontractors,” he said.