A version of this article ran in the December issue of Bicycle Retailer & Industry News.

HILDEBRAN, N.C. (BRAIN) — DeFeet founder Shane Cooper fondly remembers when the brand's socks were "the currency of the trade shows" in the 1990s as industry types would trade them among themselves.

That was back when DeFeet was the only custom cycling sock brand and before China entered the manufacturing scene with cheaper production. While some in the industry couldn't understand Cooper's insistence on manufacturing domestically, his vision was to create a "microsockery" true to his core principals: sustainability and performance.

It remains the same today at DeFeet, which celebrated its 30th anniversary in November. All of the company's poly, nylon, and lycra comes from an 80-mile radius of its headquarters. DeFeet also uses the recycled performance fiber Repreve. Cooper excitedly told BRAIN at the end of October that the brand officially will announce soon it has obtained Responsible Wool Standard certification, a voluntary designation that addresses the welfare of sheep and the land they graze on. DeFeet gets its wool from Shaniko Farms in Oregon.

"And (the wool) comes to South Carolina, where it gets washed, and then it goes to Valdese, North Carolina, to get dyed, back to South Carolina to get spun into yarn, and then to DeFeet. Our entire wool supply chain, from the ranch to the hands of the consumer, will be RWS certified. This is an industry first."

Fifteen years ago, DeFeet obtained wool from New Zealand, sent it to China to be washed, to England to be dyed, to Canada to be spun, and then returned to North Carolina.

As important as setting the industry standard for sustainability continues to be, DeFeet also strives to make a performance sock and to do it by offering customers and brands small-batch custom options designed with their logo.

"What we liked about (domestic manufacturing) is we had control, we could do small numbers, and we did reinvent the cycling sock," Cooper said from his office, about an hour east of Asheville.

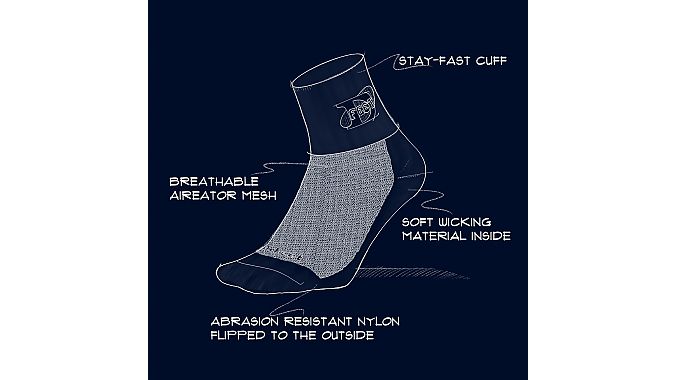

The birth of the Aireator

Precisely, DeFeet created the Aireator, manufactured by switching the nylon to the outside for durability and strength, while keeping the CoolMax soft fibers against the foot, like the "exoskeleton of a bug," Cooper said. "The inside was soft and allowed the foot to sweat. On top of that, we created the Aireator mesh weave to allow the vapor to escape and that mimicked a cycling shoe. So your foot would sweat, vapor would come out of these little vents. That was our special recipe and why everybody loved it."

At its 50,000-square-foot factory, DeFeet makes nearly all its products, including shoe covers, base layers, arm and knee warmers. But it was the sock that defined the brand. In the early years, a noteworthy accomplishment came in 1996, when Johan Museeuw of Belgium won the road world championship wearing DeFeet socks.

"We were with Team Quickstep, we were in the Tour de France," Cooper said. "So many things were happening at the pinnacle. We had athletes to be able to test our products. So all of the sudden, the yarn companies loved us because we were small and nimble and we could get their new yarns on these athletes. So it was a really cool thing to be respected instantly and have our manufacturing here."

Cooper said DeFeet also has relationships outside of cycling, including motorcycle, golf, and equestrian. "They're fit people and they want a sock that's going to perform."

While QBP and HLC are DeFeet distributors and the brand also manufactures socks for about 50 private-label companies, it also has a dealer direct portal, with no minimums. Cooper is pushing to get the word out to grow its direct IBD network, currently 300 strong. About half of the brand's business comes from custom orders for small teams or events.

"And it's not just a custom sock. It's a custom sock made here with our technology. I think IBDs will get it. Our footprint is as small as you can possibly make it. And it's responsible. I know if I'm a bike shop and I put socks near the shoes, and I tell people to try on a new pair of socks with a new pair of shoes or put socks at the counter, I know I'm going to turn those socks big time. And I'm going to make a 50-60% margin on that product."

Like a lot of the industry, DeFeet has had to raise prices — 20% last year — partly in response to supplier costs increasing and raising pay during the pandemic to retain its workforce, which numbers 35, Cooper said. He added the brand slowed production recently because of decreasing third-quarter demand. He said DeFeet's consumer website was "a savior" with about 25% of sales direct-to-consumer.

"We need our bike shops to survive and flourish, and with the consolidation that's been going on left and right, I'd like to see that independent guy stand up. We are like they are: a small business."

During the pandemic, DeFeet sales grew 12% in 2020 and fell 2% in 2021. DeFeet announced in September that it entered a multi-year partnership with Trek Factory Racing, outfitting its cyclocross and cross-country teams.

"The great thing about a cycling sock is even in the worst times, even if you can't buy a bike, you can buy some new handlebar tape and a new pair of socks, and you can go ride," Cooper said, smiling.

A new machine also can transform a brand. In 2019, Cooper purchased a direct-to-garment printer, allowing for more customization and better detail, compared to knitting. It allowed DeFeet to create the PrintMySock portal, giving the customer the option to design a single pair of DeFeet socks.

"The knitting technology is incredible, but this printing technology is space age," Cooper said.

Chasing performance

It's not all about technology and sustainability at DeFeet, however. Proven performance remains the carrot Cooper chases. After another company took over DeFeet's 20-plus-year Quickstep partnership in 2018, he thought the brand was done sponsoring World Cup and Tour de France teams. Then Lotto-Soudal called in 2020 and said it had tested the DeFeet Aireator sock in a London wind tunnel and wanted to work with the brand.

Previously, DeFeet was able to prove in its own wind tunnel test with Quickstep that its sock saved 8 watts, 4 watts more than cut and sewn aero socks made popular in England.

"Suddenly, there was a Dutch company claiming to save 12 watts with their socks," Cooper said. "I had to call BS on their claim because they used a mannequin to do the wind tunnel test, and they didn't use yaw. (Yaw is the vertical Z axis, which positions the rider against the way the wind blows.) We used a real rider and got 8 watts. So we are going back into the wind tunnel and from what we learned in 2018 and what we've learned since then with Lotto-Soudal and we are working to provide the world's fastest sock again. And we hope to have that in the Tour de France this year."

When looking back on 30 years, Cooper smiles and says he's happy with what DeFeet has accomplished, from sustainability to performance enhancements to even surviving a fire in 2001 that destroyed the company's building and halted production for nine months.

"Luckily my wife (Hope) is a financial whiz," Cooper said. "Don't give me money — I can make it, but she knows how to save it — and luckily 30 years later, we're still in business."